Transformers

Трансформатор EcoDesign 2

Впервые в Казахстане произведен трансформатор EcoDesign 2!

Инженеры Кентауского трансформаторного завода и НТЦ "Alageum Engineering" освоили выпуск трансформатора нового поколения EcoDesign 2, полностью соответствующего европейскому стандарту EN 548:2014, действующему в странах ЕС с 2015 года.

Преимущества EcoDesign 2:

▪ Сниженные потери энергии

▪ Улучшенный теплообмен

▪ Низкий уровень шума

▪ Экологичный корпус

▪ Совместим с возобновляемыми источниками энергии

▪ Подходит для умных энергосетей

Оснащён РПН с автоматическим регулированием под нагрузкой и системой мониторинга.

Технологический вклад:

В разработке трансформатора принял участие научный центр UMAY R&D, предоставивший инженерное решение для системы управления под нагрузкой и регулирования. Это стало ключевым вкладом в реализацию современных требований к интеллектуальным трансформаторам, предназначенным для интеграции и эффективной работы с "зелёной" энергетикой.

Что такое регламент EcoDesign EU 548/2014?

Это обязательный стандарт в Евросоюзе с 2015 года, направленный на сокращение потерь в трансформаторах и повышение прозрачности их энергоэффективности. Он впервые ввёл требования к трансформаторам средней и высокой мощности.

Это шаг вперёд для казахстанской инженерной мысли и устойчивого энергетического будущего!

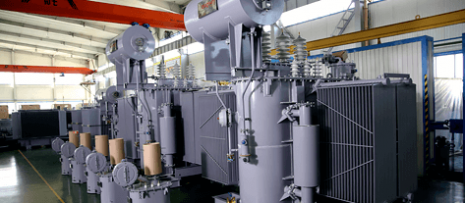

Oil transformers

The alternate design of transformers of this type makes it possible to use them in difficult conditions of industrial enterprises. The advantages of these machines include their competitive price, which in combination with the excellent technical characteristics of the machine makes it an ideal solution for industrial applications. There are types with expansion tank and hermetically sealed housing. The second version can significantly reduce maintenance, as the oil is not oxidized by atmospheric oxygen.

Typically, transformers of this type are filled with treated mineral oil. It is possible to use as a dielectric silicone or synthetic oils that have a higher ignition temperature, thereby providing greater fire safety. The body is made of corrugated sheet metal. Corrugation provides high-quality cooling of the machine during operation and compensates for the thermal expansion of the dielectric medium.

Non-oil transformers

Used in many sectors of the economy.

Designed to convert electrical energy in three-phase AC power grids with frequency of 50 Hz.

Installed in industrial premises and public buildings, which are subject to increased requirements in terms of fire safety, explosion protection, environmental cleanliness.

Operating conditions:

- Ambient temperature:- 25C to + 40C;

- Relative humidity - no more than 80% at +25 C;

- Installation height above sea level-no more than 1000 m;

- Environment - non-explosive, does not contain conductive dust.

Instrument transformers

Instrument transformers are used to extend the limits of measurement of electrical quantities in AC circuits and to separate the secondary circuits from the primary ones for the safety of maintenance personnel. Current transformers are used to supply current circuits of metering devices, control, relay protection and automation.

With the help of a current transformer, low-voltage devices connected to its secondary winding are separated from the high voltage, which ensures the safety of the maintenance personnel. Current transformers allow you to install various devices at considerable distances from those sections of high voltage circuits in which the current is measured or controlled.

Шунтирующие реакторы

Шунтирующий реактор – это устройство, обладающее большой индуктивностью и малым активным сопротивлением. Реактор потребляет реактивную мощность, тем самым снижает напряжение в сети. Шунтирующий реактор применяют для повышения пропускной способности линий сверхвысокого напряжения разгружая их по реактивной мощности, а так же для регулирования реактивной мощности и напряжения. Шунтирующие реакторы рассчитаны на высокие и сверхвысокие напряжения и могут присоединяться как к линии, так и подключаться к шинам подстанции.

Шунтирующие реакторы используются в качестве одного из средств компенсации реактивной мощности в сооружаемых, реконструируемых и эксплуатируемых электрических сетях напряжением 110 – 750 кВ, образуемых соответствующими линиями электропередачи.