«Batys Electric» LLP

admin

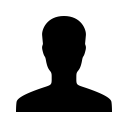

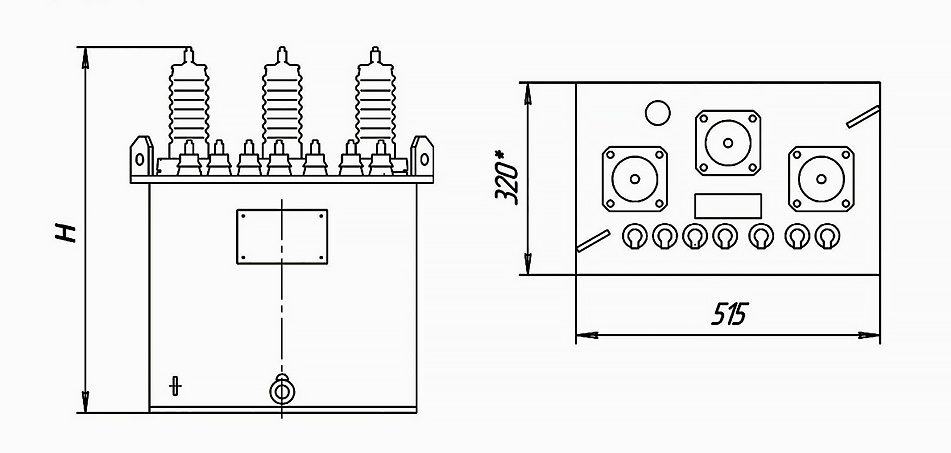

НТМИ

| Тип трансформатора | Номинальное напряжение, кВ | Номинальная мощность, кА в классе точности | ||||

| ВН | НН (осн) | НН (доп) | 0,5 | 1,0 | 3,0 | |

| НТМИ-6 | 6 | 0,1 | 0,1/3 | 75 | 150 | 300 |

| НТМИ-10 | 10 | 0,1 | 0,1/3 | 150 | 300 | 500 |

Продолжение таблицы

| Тип трансформатора | Предельная мощность, ВА | Н, мм | Масса, кг |

| НТМИ-6 | 630 | 396 | 80 |

| НТМИ-10 | 1000 | 486 | 85 |

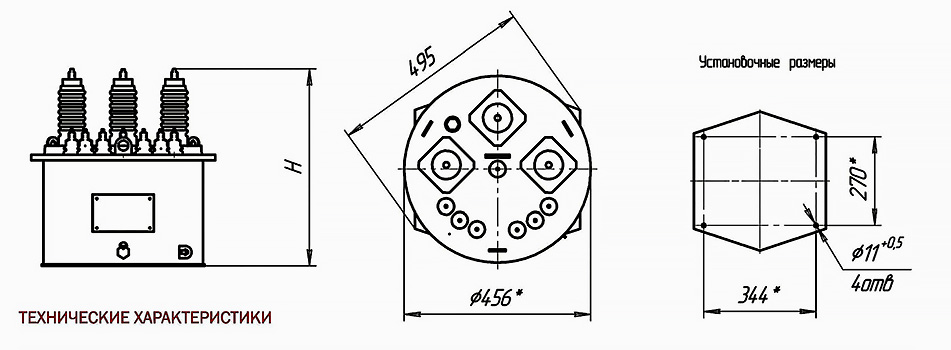

НОМ

| Тип трасформатора | Номинальное напряжение, В | Номинальная мощность для классов точности, ВА | |||

| первичной обмотки | вторичной обмотки | 0,5 | 1,0 | 3,0 | |

| НОМ-6-УЗ | 6000 | 100 | 50 | 75 | 200 |

| НОМ-10-УЗ | 10000 | 100 | 75 | 150 | 300 |

Продолжение таблицы

| Тип трансформатора | Предельная мощность, ВА | Схема и группа соединения | Н, мм | Н1, мм | Масса, кг |

| НОМ-6-УЗ | 400 | 1/1,0 | 440 | 155 | 325 |

| НОМ-10-УЗ | 720 | 495 | 215 | 340 |

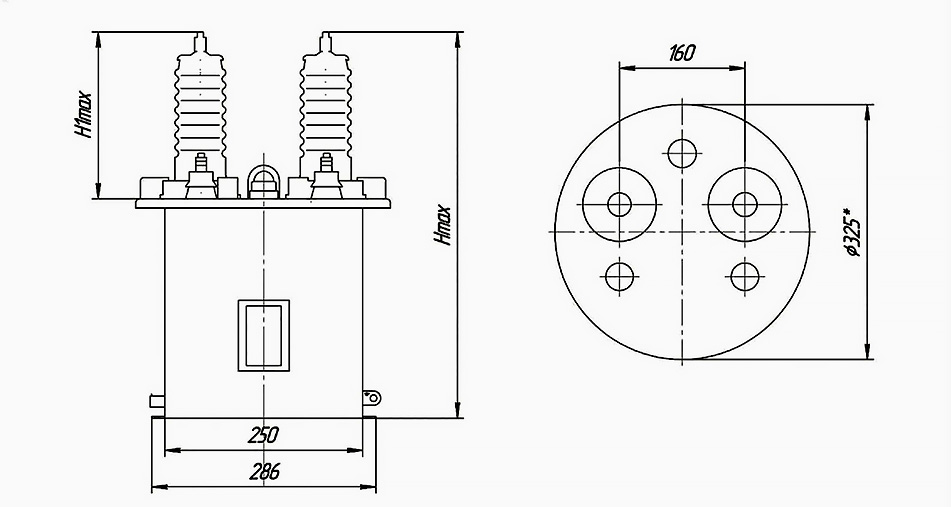

НАМИТ

| Тип | Номинальное напряжение обмоток ВН, кВ | Номинальная частота | Номинальная мощность основной вторичной обмотки ВА в классе точности |

|||||

| первичной | вторичной | дополнительной вторичной | 0,2 | 0,5 | 1,0 | 3,0 | ||

| НАМИТ-6 | 6 | 0,1 | 0,1/3 | 50 | 75 | 150 | 300 | 600 |

| НАМИТ-10 | 10 | 75 | 200 | |||||

Продолжение таблицы

| Тип трансформатора | Мощность дополнительной вторичной обмотки, ВА | Предельная мощность вне класса точности, ВА | ||

| НАМИТ-6 | Основной вторичной обмотки | Дополнительной вторичной обмотки | Трансформатора | |

| НАМИТ-10 | 30 | 900 | 100 | 1000 |

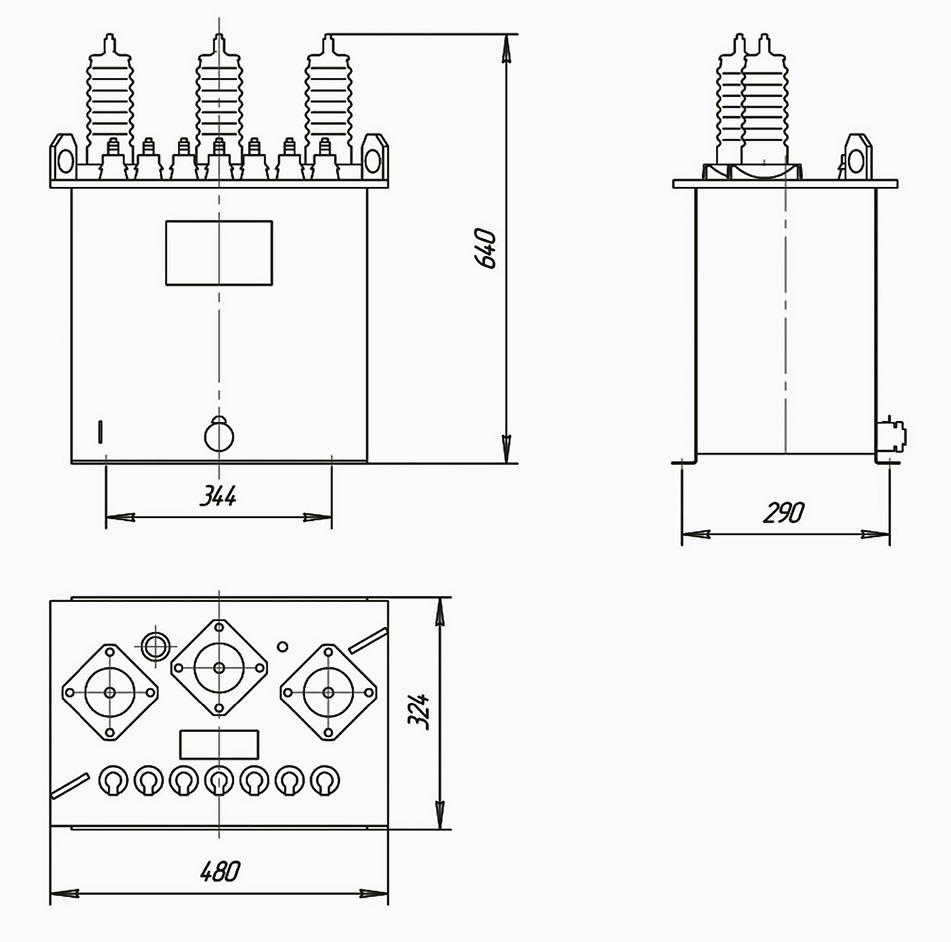

НАМИ

| Тип трансформатора | Номинальное напряжение обмоток, кВ | Мощность вторичных обмоток, ВА | Класс точности в номинальном режиме | Н, ЛАМ | Масса, кг | |||

| ВН | НН (осн) | НН (доп) | основных | дополнительных | ||||

| НАМИ-6 | 6 | 0,1 | 0,1/3 | 75 | 30 | 0,2 | 555 | 106 |

| НАМИ-10 | 10 | 0,1/3 | 615 | 115 | ||||

JSC “Electromontazh”

Elektromontazh JSC (JSC “ELMO”) for more than 80 years has been one of the largest electric installation organizations in Kazakhstan and carries out a full complex of works on construction and reconstruction of electrical installations of any complexity. The company is a part of the holding company "Alageum Group" - the market leader in the field of electricity.

JSC "ELMO" performs the following types of work:

- design of engineering systems and networks;

- installation of switchgears and substations up to 220 kV and above;

- installation of overhead power lines with voltage up to 500 kV and above;

- installation of current distributors and busbars with voltage up to 35 kV;

- installation of grounding;

- manufacture of electrical products and cable trays with the provision of hot-dip galvanizing services;

- manufacture of electrical structures with voltage up to 10000 V;

- earthworks and commissioning;

- construction of bearing and enclosing structures of buildings and structures for electrical purposes;

- special construction and installation works;

- works on the installation of external engineering networks and constructions;

- works on the installation of internal engineering systems;

- the installation of electrical equipment and Control and testing Instrumentation;

- installation, adjustment and maintenance of fire alarm and automation;

- operation of electrical networks and substations;

- special works on protection of structures and equipment.

Since the entry of ELMO JSC in the "Alageum Group" a new milestone has begun in the history of the company. Since 2012, the company has significantly increased its economic potential, business processes have been systematized, and work standards have been raised. The Park of special machinery and equipment has been updated, reconstruction of production facilities has been carried out, additional branches have been opened in Astana, Pavlodar and Taldykorgan.

Today "ELMO" brings together more than 10 specialized Assembly Department (AD) located in all regional centers of Kazakhstan. Each AD has a powerful material and technical base with production, warehouse and administrative premises, as well as an updated fleet of special equipment. As part of JSC "Electromontazh" the plant of electrical products is operating, which manufactures trays, racks, shelves, cable ducts and perforated box with the provision of hot dip galvanizing

Executive Director Umbetaliyev E.E.

JSC “KTP”

Kentau transformer plant JSC is known as the leading Kazakhstan producer of the transformer equipment of wide application delivered for all branches of economy, including power industry, metallurgy, mechanical engineering, transport, oil and gas complex, housing and communal sector. The equipment with the Kentau transformer plant brand reliably works in all territory of the CIS and Central Asia.

For last years the list of production of plant reached more than 400 names. The main strategy of JSC “KTP” is delivery to the market of the best electrotechnical production conforming to requirements of consumers for quality, the price, delivery conditions and the provided service. Today, the plant is rightfully the leader of domestic electrical engineering, a leading manufacturer of transformer equipment.

JSC "KTP" in the course of modernization got rid of "loose" production equipment of the USSR and switched to the latest high-tech equipment of leading Western and European companies, which are considered to be one of the best in the world. The share of local content in the manufacture of equipment is 85%.

The recommended period of technical operation of transformers is 25 years, but in fact, with proper operation and timely maintenance, the transformer operates uninterruptedly for 40-50 years. On the basis of JSC "KTP" since 2014 successfully operates Polytechnic College, where students receive dual training, applying their knowledge in the production of the plant. Every year the College produces more than 100 specialists, who are subsequently employed at the plant and in HC "Alageum Electric".

“AEMP” LLP

Almaty Electromechanical plant LLP (LLP "AEMP") was established in 1959 as a company of all-union appointment. Its products were focused mainly on the needs of railways of the Ministry of Railways of the USSR. In the early 90-ies, like many other enterprises of the CIS, the plant began to decline.

In 1999, during the implementation of the sector program of privatization and restructuring of state property in the transport and communication complex of the Republic of Kazakhstan, the enterprise was reorganized into Almaty Electromechanical plant LLP (LLP "AEMP") and became a part of the holding company "Alageum Electric". From this moment the intensive development of the enterprise began, questions of equipment with its modern hi-tech equipment and providing with qualified personnel were solved.

At present, "AEMP" LLP is one of the leading manufacturers of electrical equipment of 0.4 – 35kV voltage class in the Republic of Kazakhstan, complete distribution devices (CDD) of indoor and outdoor installation, complete transformer substations (CTS), as well as standard and non-standard power distribution cells (SAC series cameras), cabinet structures. The products are manufactured at reliable and trusted easel equipment of leading European companies (EUROMAC, GASPARINI, DURMA, BYSTRONIC), which ensures high quality of manufactured products in the shortest time. The plant is guided by the philosophy and practice of continuous improvement processes "Kaizen".

The main consumers of production of plant are both the population, and industrial, oil-extracting, power sectors of economy, including the regional power companies of the CIS. Production of Plant is demanded in the neighboring countries (Kyrgyzstan, Uzbekistan, Tajikistan, Afghanistan) and proved as reliable and durable. This year the plant started mastering OS-35,110 kV.

The products manufactured by the plant are certified in the State standard of the Republic of Kazakhstan, comply with the Technical regulations of the Customs union, as well as have certificates of origin of ST-KZ form. The quality management system ISO 9001:2000 was implemented in 2004 and certified by the international certification body KEMA (Holland). The plant has a license of the first category for project activities and is included in the Register of domestic commodity producers of the Republic of Kazakhstan.

Export

The development of foreign markets by "Alageum Electric" began in 2001. Today, export deliveries go to Russia, Central Asia, Afghanistan and Azerbaijan. The share of exports in the total sales of the company is 50%. According to this indicator, the holding confidently competes with the leading manufacturers of Belarus, Ukraine and Russia

The new strategic goal is to increase the share of exports to 60% by 2030. A set of measures to expand the range of products and services, access to the markets of the CIS countries, the South Caucasus and Iran is aimed at achieving the ambitious goal. Having taken strong positions in the domestic market, "Alageum Electric" confidently masters trading areas of the neighboring countries. In 2005 the structural enterprise CJSC “Kyrgyzenergoremont” on rendering services in the sphere of the high-voltage and low-voltage equipment, repair of turbines, deliveries of the electrotechnical equipment is created

In 2013 the Russian representative office of the company in Moscow was opened. The scope of its activities is expanding its presence in the Russian market by creating a dealer network, strengthening the status quo of the brand "Alageum" abroad.

The new export vector of the company allowed to activate work on expansion of client base, specification of potential opportunities for increase of the product range demanded in the neighboring countries. For this purpose the company has all necessary: high-quality goods, competitive prices and a dealer network of sales.

Installation and commissioning

JSC Electromontazh (ELMO) - one of the largest installation organizations in the Republic of Kazakhstan specializing in performance of electric installation works on objects of any complexity with delivery them "turnkey". Development of "ELMO" began with creation in 1935 of Bureau of design and installation works in Almaty. Since 2012 a new milestone came in the history of the company – JSC "ELMO" became a part of the "Alageum Group".

Это позволило значительно усилить его экономический потенциал, отточить бизнес-процессы, повысить стандарты работ. Обновлен парк спецтехники и оборудования, проведена реконструкция производственных баз, дополнительно открыты филиалы в городах Астана, Караганда, Петропавловск и Павлодар.

Today "ELMO" unites more than 10 specialized Assembly Departments (AD), located in all regional centers of Kazakhstan. Each AD has a powerful material and technical base with production, warehouse and administrative facilities, as well as a fleet of special equipment. As part of JSC "ELMO", a plant of electrical products, which manufactures trays, racks, shelves, cable racks and cable ducts, providing services of hot dip galvanizing..

During the years of its activity, "Electromontazh" successfully performed work at the facilities of the oil refining industry, nonferrous and ferrous metallurgy, chemical and nuclear industry, construction industry, agricultural, housing and social and cultural facilities, as well as the construction of energy facilities.

Among the projects performed by the company are such complex works as:

- power supply of the Residence of the President and the Parliament building;

- construction of 110/10 kV substation and 110 kV Kumkol-Akshabulak air line (AL)»;

- substation "Akshabulak" 110/6 kV and 110 kV overhead line;

- interregional 500 kV overhead line "North Kazakhstan-Aktobe region»;

- 10 kV long-haul overhead line of the Kenkiyak-Kumkol oil pipeline»;

- power supply of new Railways "Shar-Ust-Kamenogorsk", "Aktau – Mangistau port", "Khromtau – Altynsarin", "Uzen – State border", "Zhetygen – Korgas", Almaty metro;

- reconstruction and modernization of gas pipelines of JSC "KazTransOil»;

- works in the construction of the oil refining complex "Karabatan».

Equipment delivery

The network of branches and representative offices of JSC "Alageum Electric" provides supply of industrial equipment and maintenance in all regions of Kazakhstan. Service engineers of the company help customers to make an individual calculation and choose a specific model of electrical equipment, as well as to conduct a comprehensive installation and commissioning, carry out warranty and post-warranty maintenance of equipment.

Among the numerous projects performed by the company such works as:

- repair of transformers АТDTsТG -9000/220/110/10 kV" for JSC "KEGOC»;

- reconstruction of transformer substation for the Central office of the Ministry of Internal Affairs;

- reconstruction of the GPP-Kuulus with the replacement of OCDD 6 kV to CDD with vacuum circuit breakers with modular building, CBPB for LLP"MAEK-Kazatomprom»;

- construction and installation works and power supply of md. Sarytau of Zachagansk village, 2nd and 3rd queue.